-

Home

Home

- HOME

- STORAGE

-

SHIPMENTS

HUMIDITY

- Silicagel Desiccant Bags (Standard)

- Desiccant Clay Bags

- Molecular Sieve Desiccant Bags

- Home Desiccants

- Humidity Stabilizer

- Hygrometers

- Humidity Indicators

- Shipping containers

- Molecular Sieve Desiccant cartridges

- Silica Gel Desiccant cartridges

- Data Loggers

- FOOD

- ART

- SECTORS

- APPLICATIONS

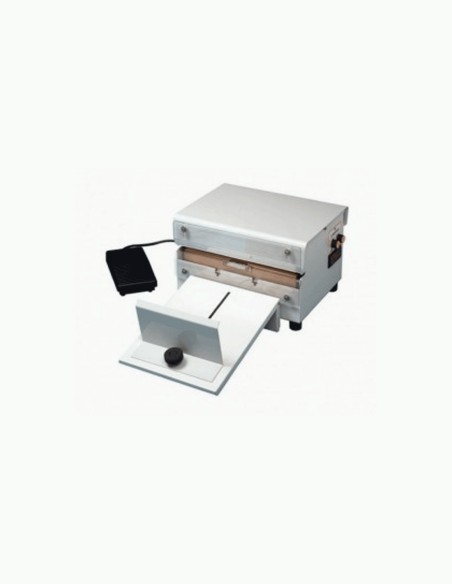

Semi-automatic Heat Sealer

D0200412

€3,369.85

€2,785.00

tax excl.

Delivery 2 to 3 weeks

The Lamino 302 is a semi-automatic heat sealer used for sealing flexible synthetic packaging. This heat welding is an effective and reliable packaging solution for sealing laminated pouches as well as cellophane, aluminium, coated paper or PP films. But it has to be noted that it cannot be sealed with polyethylene.

The semi-automatic sealing machine contains a digital LCD control panel from which the sealing time and temperature can be modified and adjusted. The latter can be set up to 200 °C with an error of +/- 5 °C. To effectively prevent film delamination and at the same time achieve a 13 mm strong seal, the electric sealing tape is constantly heated and applied at high pressures.

You might also like

€216.59

€179.00

tax excl.

Continuous sealing machine D-545 AV

€7,937.60

€6,560.00

tax excl.

Horizontal sealing machine D-545 AH

€6,491.65

€5,365.00

tax excl.

Semi-automatic Heat Sealer

€3,369.85

€2,785.00

tax excl.

The small, semi-automatic Lamino tabletop heat sealer is perfect for sealing laminated films and other flexible packaging.

The digital control panel of the heat sealer allows for easy and precise adjustment of temperature and sealing time. A solid and consistent seal with a 13 mm profile ensures the preservation, conservation and protection of the quality of your products by preventing film delamination.

A special "insert edge guide" ensures that the sealing is straight and in the same position on the bag. The sealing process starts when the sealing bars reach the pre-set temperature, reducing the amount of wasted film and improving packaging efficiency. As a result, your products are guaranteed to retain quality, have a long shelf life, and are well protected for storage or transport.

The temperature controller integrated into the sealing machine ensures consistent and durable sealing results.

- Recommended for:

- Sealing bags in polypropylene, aluminium, materials coupled with heat-sealable paper.

- Display

- Large, clear 1 line by 16 character alphanumeric LCD.

- Sealing length

- 300 mm

- Sealing width

- 13 mm

- Regulations

- Built according to EC standards

- Weight

- 15 kg

- Dimensions

- 350 x 280 x 225 mm

- Housing material

- Epoxy

- Welding temperature

- 200°C (+/- 5°C)

- Film thickness

- 2 x 200 μm (min 2x20)

- Sector

- Bakery, Coffee and tea. Fruits and vegetables, industrial components, office supplies, packaging and logistics, animal feed, retail store

- Type of sealing

- Crimped Profile Seal

- Seal bars

- Bi-active

- Temperature alarm

- +/- 5 °C (compared to set temperature)

You might also like